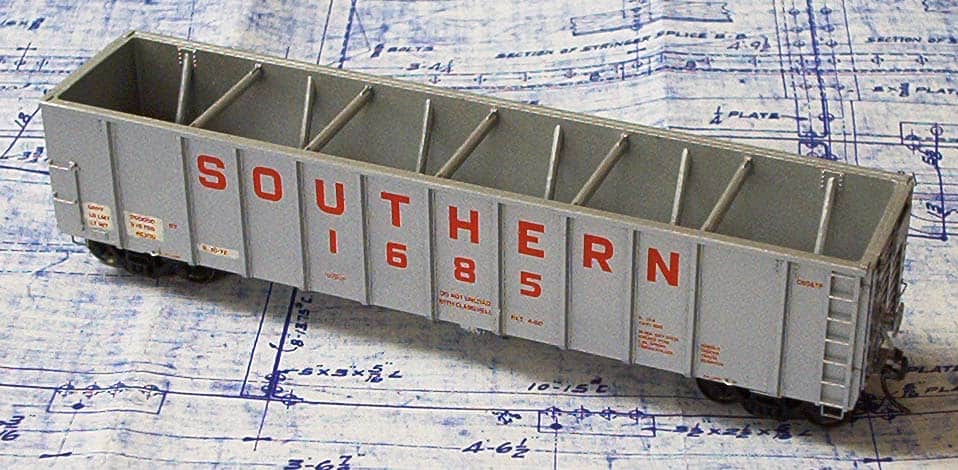

Smoky Mountain Model Works, Inc.

Asheville, North Carolina • USA

Asheville, North Carolina • USA

Using 21st Century Technology to Create Functional Parts

Smoky Mountain Model Works, Inc. opened in 1994 as a part-time model railroad kit manufacturer centered around hand-made styrene mold patterns and flat urethane castings. Polyurethane resins were limited, often brittle, and did not tolerate heat well.

In February 2003, we made the leap to a full-time S-Corporation utilizing state-of-the-art 3D CAD software (Solidworks), Stereolithography (SLA), rubber mold/cast urethane technologies. Injection molding was added in 2006. Our first in-house SLA (resin) printer was added in 2020.

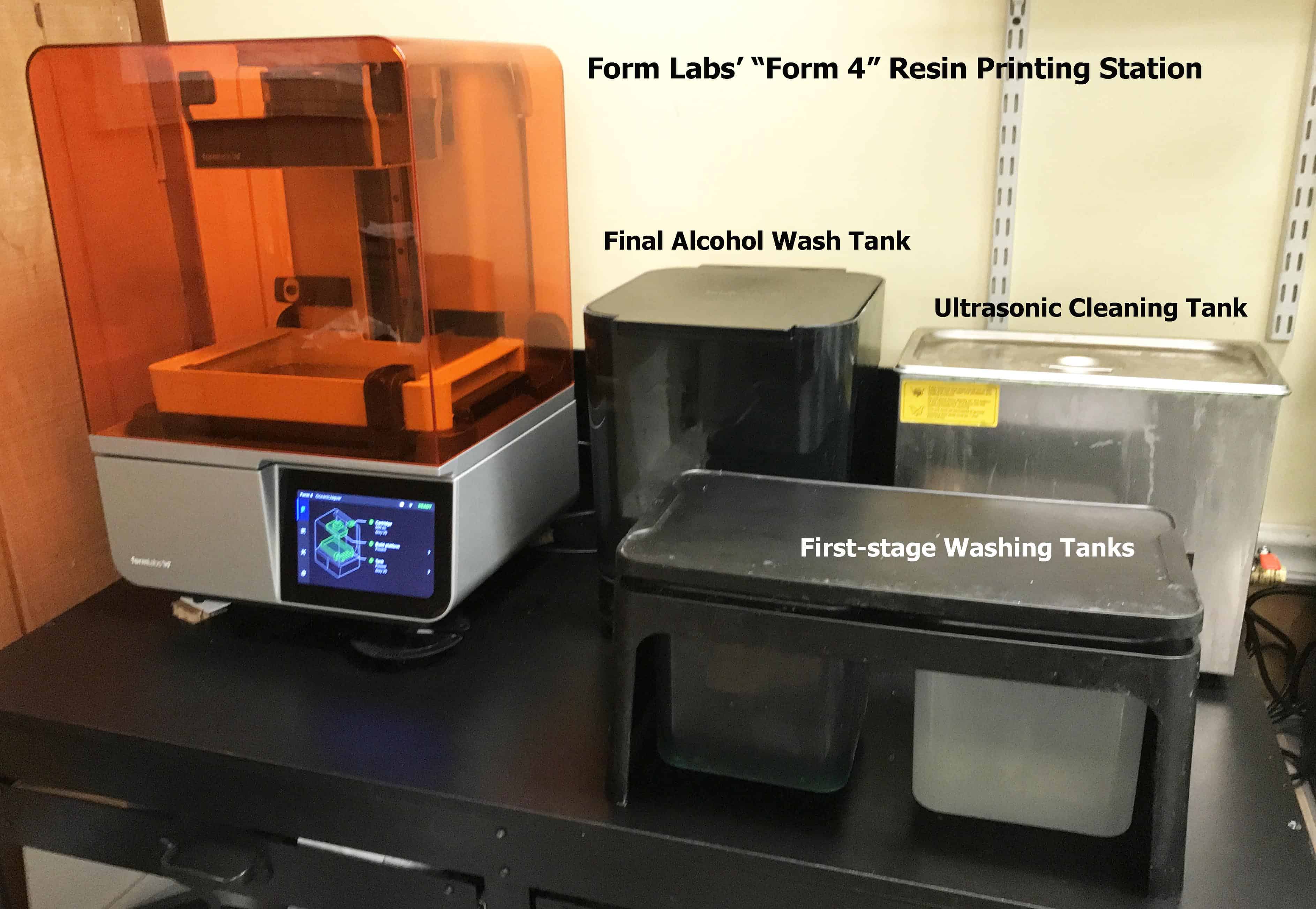

In mid-August 2024, we upgraded from our tried 'n true "Form3" to the "Form4", considered by FormLabs to be their first production printer due to much faster speed, greater accuracy, larger print size, and reformulated resins. The upgrade allows us to reintroduce out-of-production products that no longer justify the time-consuming rubber mold/urethane casting process.

Many parts and products once cast in urethane are being converted to 3D printing which saves YOU assembly time while maintaining the same price and quality you expect from us.

Click on the links and photos to learn more about our services. Contact us via email or phone to discuss YOUR specific project.

In February 2003, we made the leap to a full-time S-Corporation utilizing state-of-the-art 3D CAD software (Solidworks), Stereolithography (SLA), rubber mold/cast urethane technologies. Injection molding was added in 2006. Our first in-house SLA (resin) printer was added in 2020.

In mid-August 2024, we upgraded from our tried 'n true "Form3" to the "Form4", considered by FormLabs to be their first production printer due to much faster speed, greater accuracy, larger print size, and reformulated resins. The upgrade allows us to reintroduce out-of-production products that no longer justify the time-consuming rubber mold/urethane casting process.

Many parts and products once cast in urethane are being converted to 3D printing which saves YOU assembly time while maintaining the same price and quality you expect from us.

Click on the links and photos to learn more about our services. Contact us via email or phone to discuss YOUR specific project.

Smoky Mountain Model Works, Inc. Asheville, NC 28805

Ph.: (828) 777-5619 (10-5 M-F)

Email: jimking3@charter.net

Ph.: (828) 777-5619 (10-5 M-F)

Email: jimking3@charter.net

Double click to edit

Two sisters from a local shelter now keep Isabella "company" and frequently camp out on my desk while I'm designing new products.